Molding the Future, One Part at a Time

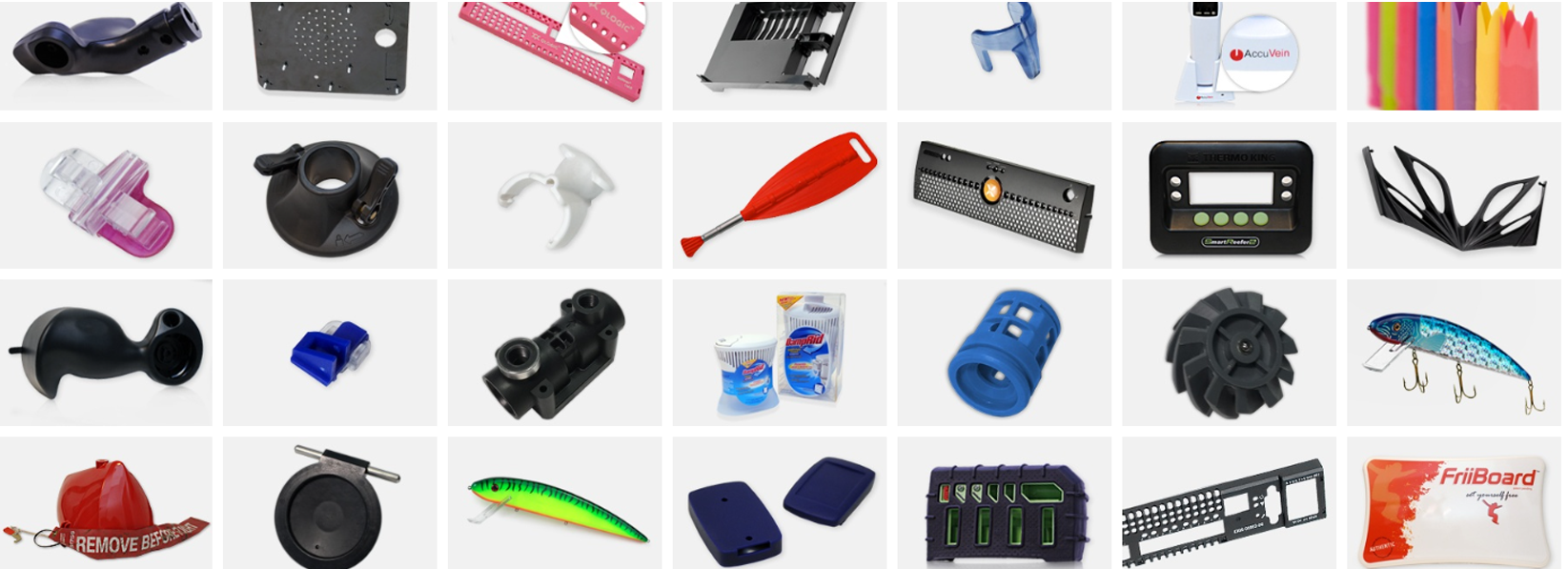

Innovation isn’t just a concept at Intek — we inject it and extrude it into everything we do. As your trusted partner in custom plastic injection molding and extrusion, we produce high-precision, tight-tolerance components and assemblies designed to fit your exact needs.

Whether it’s a straightforward single-process mold or an intricate, automation-driven design, our expertise ensures that we deliver excellence at every stage.

From engineering-grade resins to exotic materials, we help you navigate the complexities of manufacturing while dodging potential pitfalls and delivering the perfect solution. With Intek, you get more than just parts — you get peace of mind and consistent, precision finished parts.

Your Vision, Our Precision

Our tenured engineers and production team are here to turn your ideas into reality with unmatched precision and efficiency. We’re not just about making parts; we’re about building lasting partnerships. That’s why we pride ourselves on clear communication, on-time delivery and consistent high quality.

We’re Pressing All the Right Buttons (and Tonnage)

No matter the size of your components, we’ve got you covered — from micro molding to 36 inches. Our AS 9100D-certified, ISO 9001-certified, UL registered, FDA medical device manufacturer certified and ITAR-registered facilities are equipped with cutting-edge technology and presses ranging from 35 to 1,000 tons, ensuring we can handle everything from intricate small parts to large-scale components with precision.

One to 1,000 parts or Full Production – We’ve Got You Covered

Need one prototype to test your big idea? We’re in. Scaling up to 100, 1,000 or full production? We’re already there. With advanced in-house technologies at our fingertips, we ensure reliable, repeatable processes with rock-solid qualification documentation at every step. No guesswork. No surprises. Just precision parts and assembles, done right—every time.

- Quick-to-market parts and tooling (because time is money!)

- From a single part to full production – Intek gets it done

- Wide material selection thanks to our close supplier relationships

- Automated solutions with robotics (because efficiency and accuracy are key)

- Thin wall molding for lightweight yet durable parts

- Hot runner molding for cost-effective, high-quality results

- Insert molding and elastomeric over-molding for multi-material magic

- Secondary services, assembly and inventory management (because we’re all about making your job easier!)

Already Invested in Tooling? No worries!

We’ve successfully managed hundreds of tool transfers, so you’re in expert hands. Our transfer tooling program takes the pressure off, ensuring better part quality, superior service and pricing that keeps both your budget and timeline intact. Let us handle the heavy lifting while you focus on what matters most!

Intek shapes solutions that meet your needs. Ready to shape something great together? Let’s go!