Think It. Prototype It. Market It. Go.

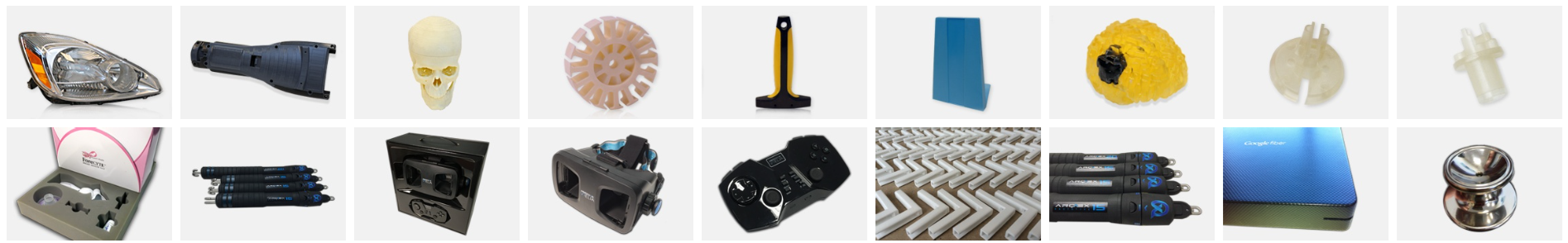

Intek Plastics doesn’t just push the limits — we shape them. Our custom prototype extrusion and molding dies as well as other rapid prototyping technologies let you create real, testable prototype parts, allowing you to see exactly how your concept performs in R&D builds.

No guesswork, no close enough simulations — just actual plastic parts providing real-world insights, faster testing and smarter decisions. Our rapid prototyping services, powered by cutting-edge additive manufacturing, make it easier than ever to bring your ideas to life — quickly, precisely and repeatably. With fast design iterations, consistent part accuracy and rapid speed to market, we help you stay ahead of the competition.

Why Prototype with Intek?

Waiting is so last century. Whether you need proof-of-concept, a functional show model or on-demand low-volume production, we provide tailor-made solutions for your project. Plus, with our rapid prototyping and injection molding division, Five Star Plastics, we bring decades of experience to the table (or, in this case, the printer bed). Our streamlined process reduces development cycles, helping you refine your design quickly and efficiently while minimizing costs.

Our Rapid Prototyping Superpowers:

- Additive Manufacturing: Layer by layer, we make the impossible possible.

- 3D Printing Processes: High-quality, high-speed and high-fidelity.

- Cast Urethane for an Injection Molding Look and Feel: Production-quality parts, perfect for low-volume runs (<250 parts/year) or affordable ramping up.

- Fast Design Iterations: Quickly refine and perfect your concept without delays.

- Consistent and Repeatable Accuracy: Get reliable, production-quality results every time.

- Largest Build Envelope for SLA and SLS: Go big or go home—we’ve got room for it all.

- FAIRs and PPAPs: Get full documentation for validation and approval.

- Low Volume Production: Need just a few? We’re on it.

- Functional Show Model Prototypes: Look sharp, work smart.

- Multi-Level Finishing Standards: From rough draft to showroom ready.

- Custom Coatings: Clear, metal, epoxy and more—we make it shine.

- Insert and Decorative Features: The finishing touches that take it from prototype to perfection.

- Speed to Market: Get your product out there faster and stay ahead of the competition

Speed and functionality matter. Whatever your project demands, we have in-house technology and expertise to make it happen. Your next breakthrough is just a print away. Let's prototype the future. Request a quote today.